The difference may seem subtle but in practice the time interval from successful acceptance testing to production work of the equipment may vary considerably. Why is that so? Because for a customer it’s a one-time (or rare) project so it’s hard to anticipate all possible issues. For the supplier, on the contrary, it’s a regular process. So they’ve got a lot of experience that may be used to help the customer launch the equipment without delays.

And this is the moment of truth: in the true customer-oriented world may means must!

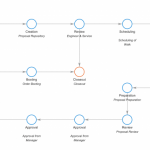

Following the principle “what’s good for our customers is good for us”, the company revised the process so that it is now considered complete when the equipment produces goods, not when it just passed the testing. The duration of the process from start to this moment is used to measure overall process performance.

This principle should be followed with caution however. We must strive to deliver value to customers indeed but we should ask ourselves – are they willing to pay for it? And we shouldn’t forget about costs either. Achieving maximum customer’ satisfaction may lead to increased costs, unsatisfied investors, smaller budgets for new products and development etc.

Yet in this particular case it’s probably about supporting customer with advice and recommendations based on the company’s experience: good value for a small cost.

What can be learned from this case: “as you name your process and define its boundary our customer will be satisfied”.

Getting back to end-to-end processes, at Comindware we believe that an end-to-end is a process from the very beginning to the very end named as “… to …” for example “lead to cash”, “idea to product”, etc.

Sounds provoking? Please feel free to comment below, your opinion counts for us.